Commercial Kitchens

The SEC-K is an advanced commercial kitchen gas detection system designed to enhance safety and optimize energy efficiency. By monitoring carbon dioxide (CO2) levels and kitchen temperature, the SEC-K automatically adjusts the ventilation rate to minimize energy consumption and associated costs. During busy periods, when CO2 levels or temperature rise, the system increases ventilation and then reduces it automatically once conditions stabilize.

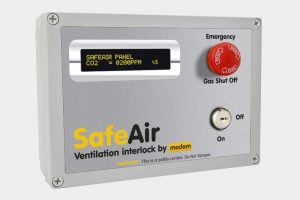

This intelligent control ensures that ventilation starts from a default minimum and adapts dynamically to the kitchen environment. Additionally, the SEC-K provides an extra layer of safety by isolating the gas supply if CO2 levels exceed 2,800 ppm, which can occur when grease filters in the ventilation system are not cleaned regularly.

To comply with BS 6173:2009, the system isolates gas if any fans are not operating correctly. It also performs a gas leak test at startup. Even when flame safety devices are installed on all kitchen appliances, these devices can take up to 10 seconds to activate if the gas supply is interrupted. The SEC-K addresses this by conducting an integrity check of the pipework, ensuring the system is safe to use.

The SEC-K supports natural gas, LPG, and CO2 detection, offering a comprehensive solution for commercial kitchens. With its focus on safety, energy efficiency, and compliance, the SEC-K is an essential component for any modern commercial kitchen gas detection system.